- Class 150 & Class 300

- Size Range 1/2” thru 8” Full Bore

- M15F – ISO 5211 Direct Mount Pad

- M30F – ISO 5211 Mount

- Body Wall Thickness ASME B16.34

- End Connections: RF Flanged

- Fugitive Emissions ISO 15848

- Firesafe Tested API 607

- Anti-Static Device and Live-Loaded Packing

- Blowout Proof, Low Torque Guided Stem Design

- Wide Range of Soft and Metal Seated Options

- Manual, Electric, Pneumatic Operators

- Globally Certified and Approved

Literature

Certifications & Compliance

Sesto Valves are designed and manufactured to internationally recognized standards including but not limited to the following:

Fire Testing: API 607 Certified

Testing: API 598, API 6D, ISO 15848, B56361, ISO 5208

Design: ANSI B16.34, ANSI B16.5, ANSI B16.10, NACE MR0175, API 608

Markings: MSS-SP-25, PED, NACE

Certifications: API 607, SIL, NACE, PED, ISO 15848

Versatility & Reliability

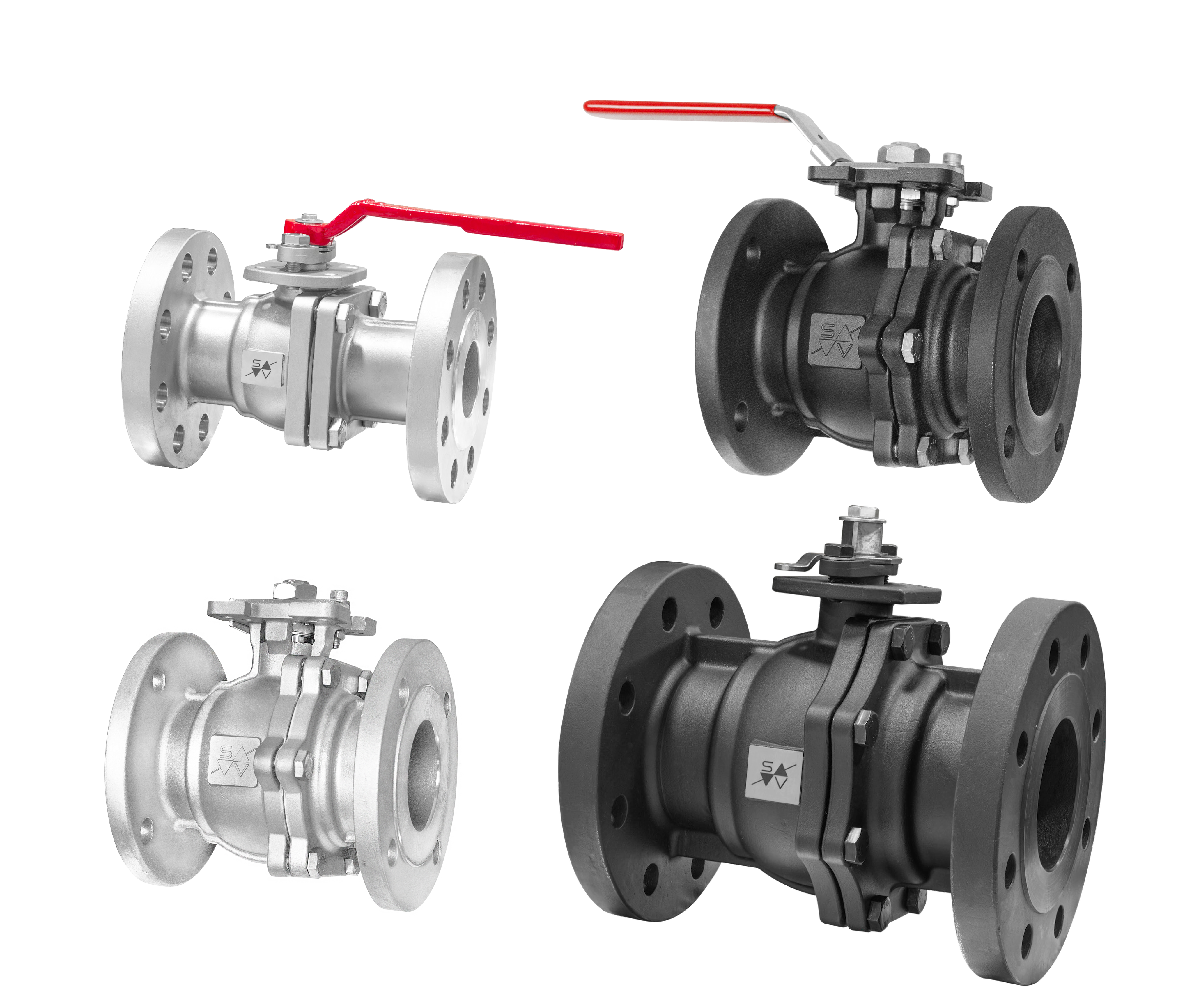

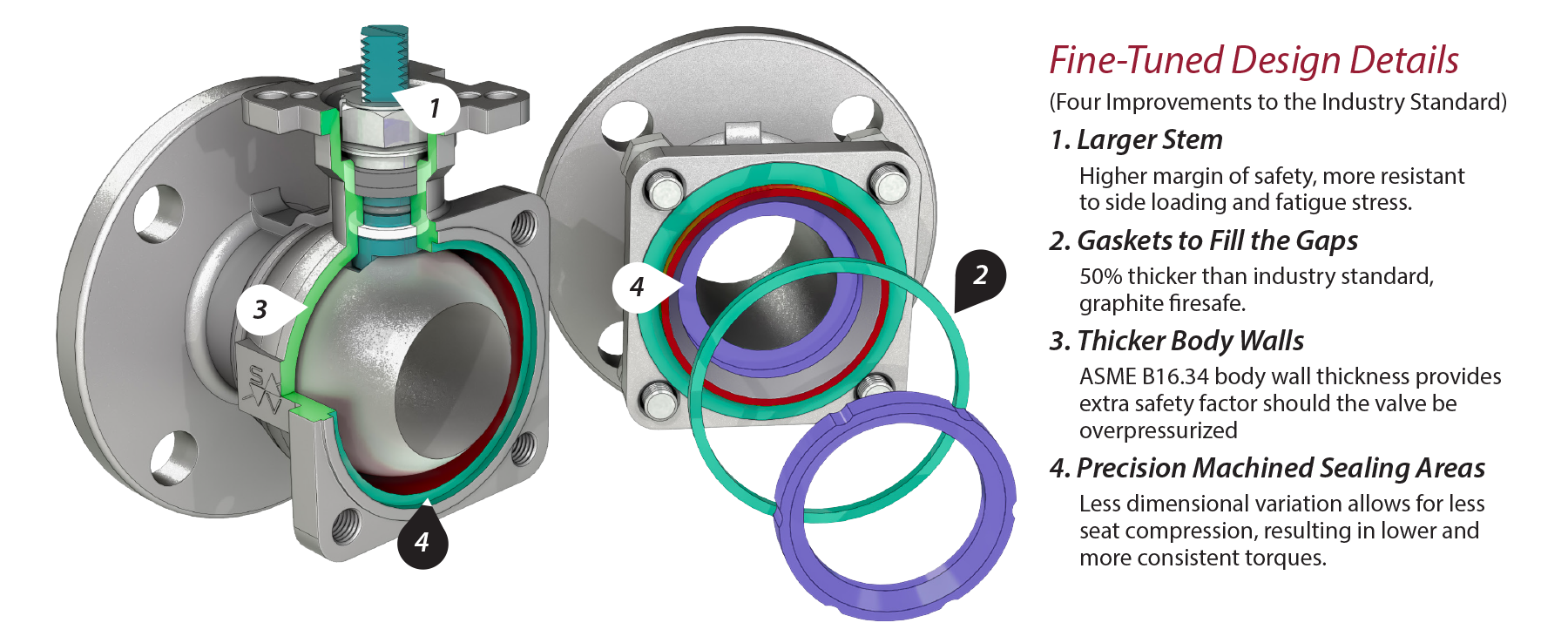

The Sesto Valves M15/M30F Series direct mount flanged floating ball valve design starts with a high quality investment cast body, designed and tested in compliance with ASME B16.34 standards. Precision machined surfaces and tighter manufacturing tolerances allow for precise assembly and fitting of body components and seals. Because of reduced dimensional variations, seats can be designed for minimal compression. This results in lower, more consistent torques and longer seat life. Every valve is factory tested and serialized for quality control and traceability.

Low Torque Design

Larger stem and seats with much less compression and precision machined sealing areas give us a consistent and reliable lower torque than our competitors.

End Connections

Flow Control & V-Ball Solutions

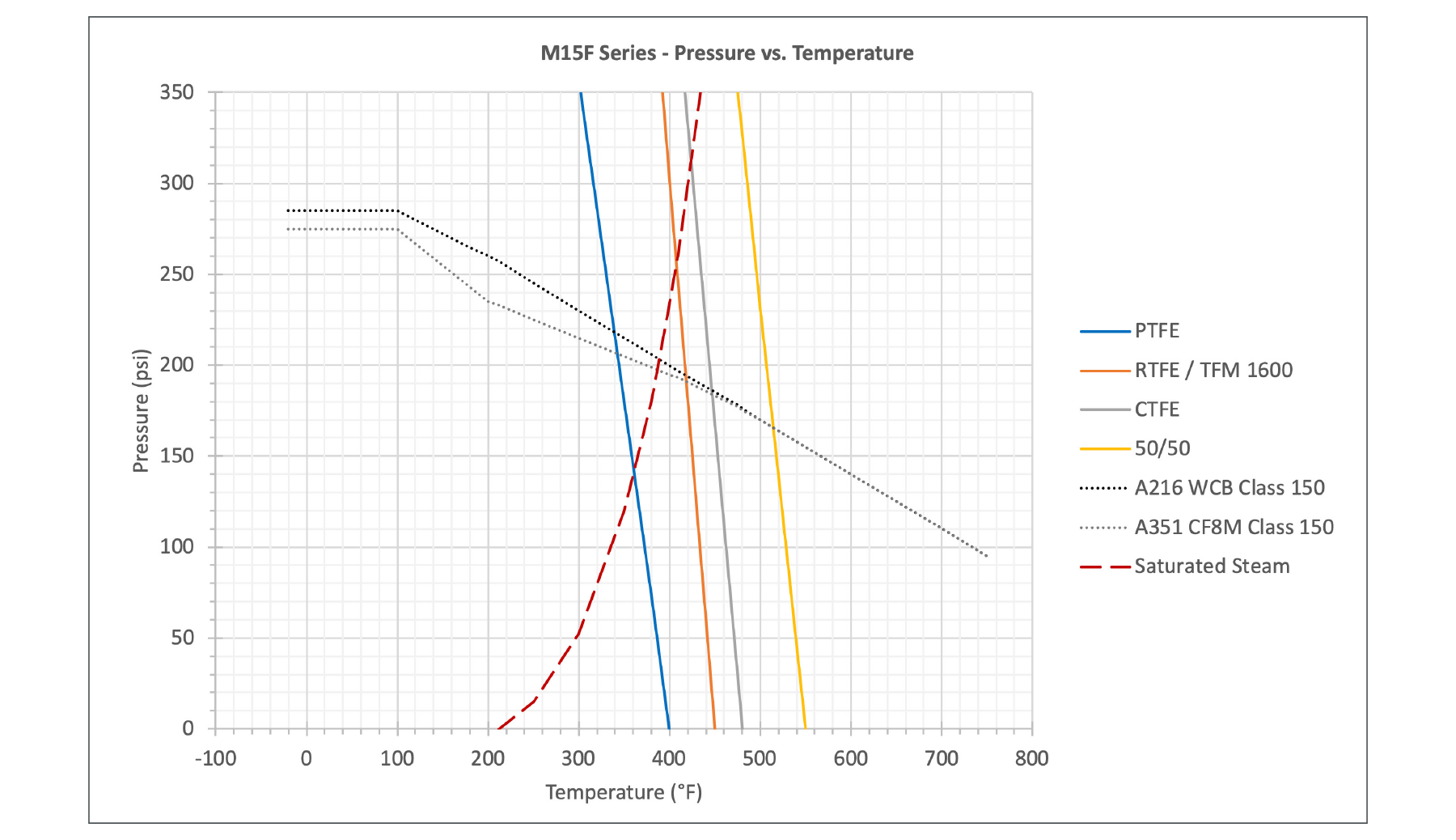

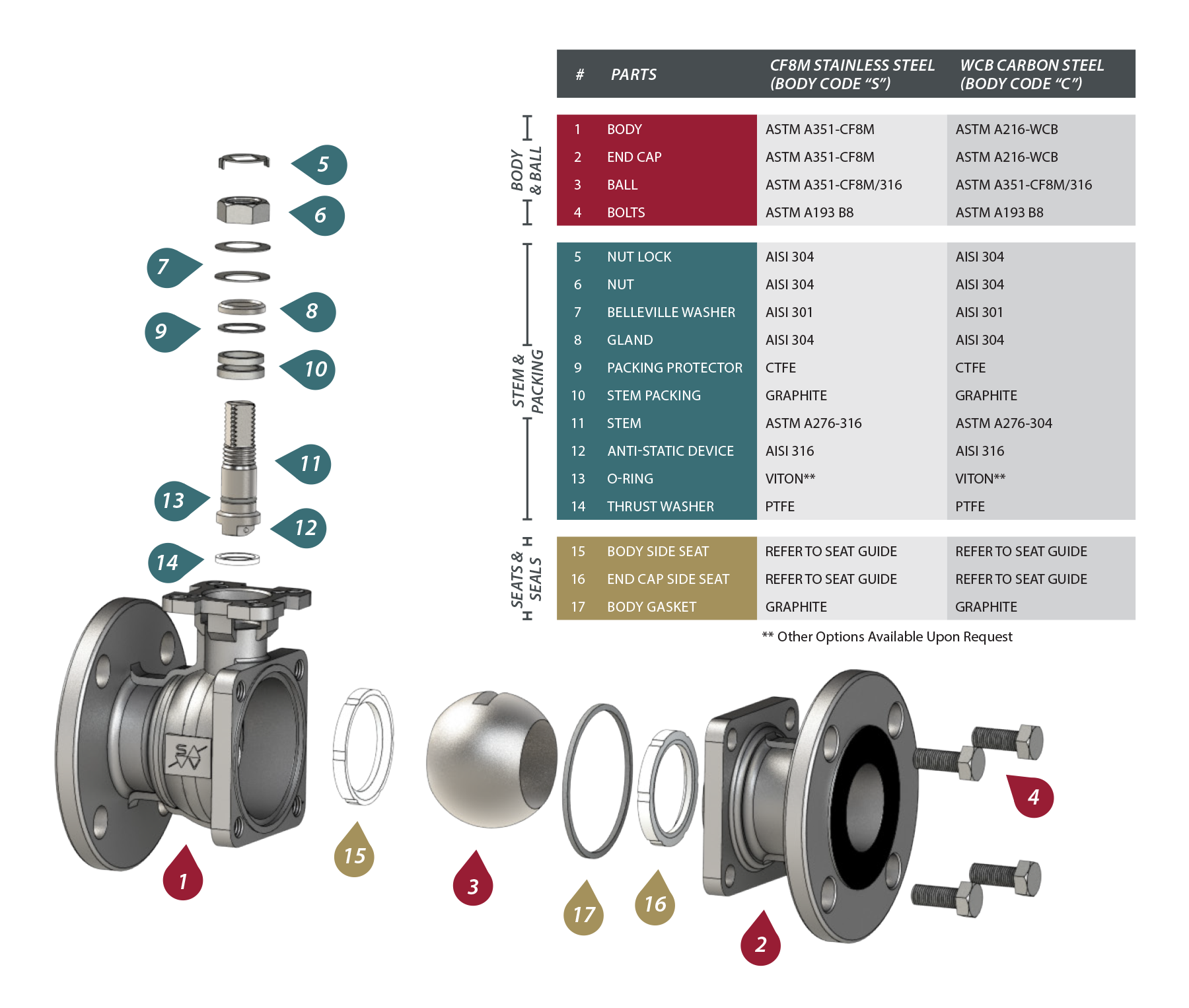

M15F | Firesafe 2-PC Flanged Class 150 | Direct Mount Design

ASME B16.34, API 608, API 607, ISO 15848, NACE MR-0175, Sil 2 Certified, Torques and Tolerances Verified for Consistency

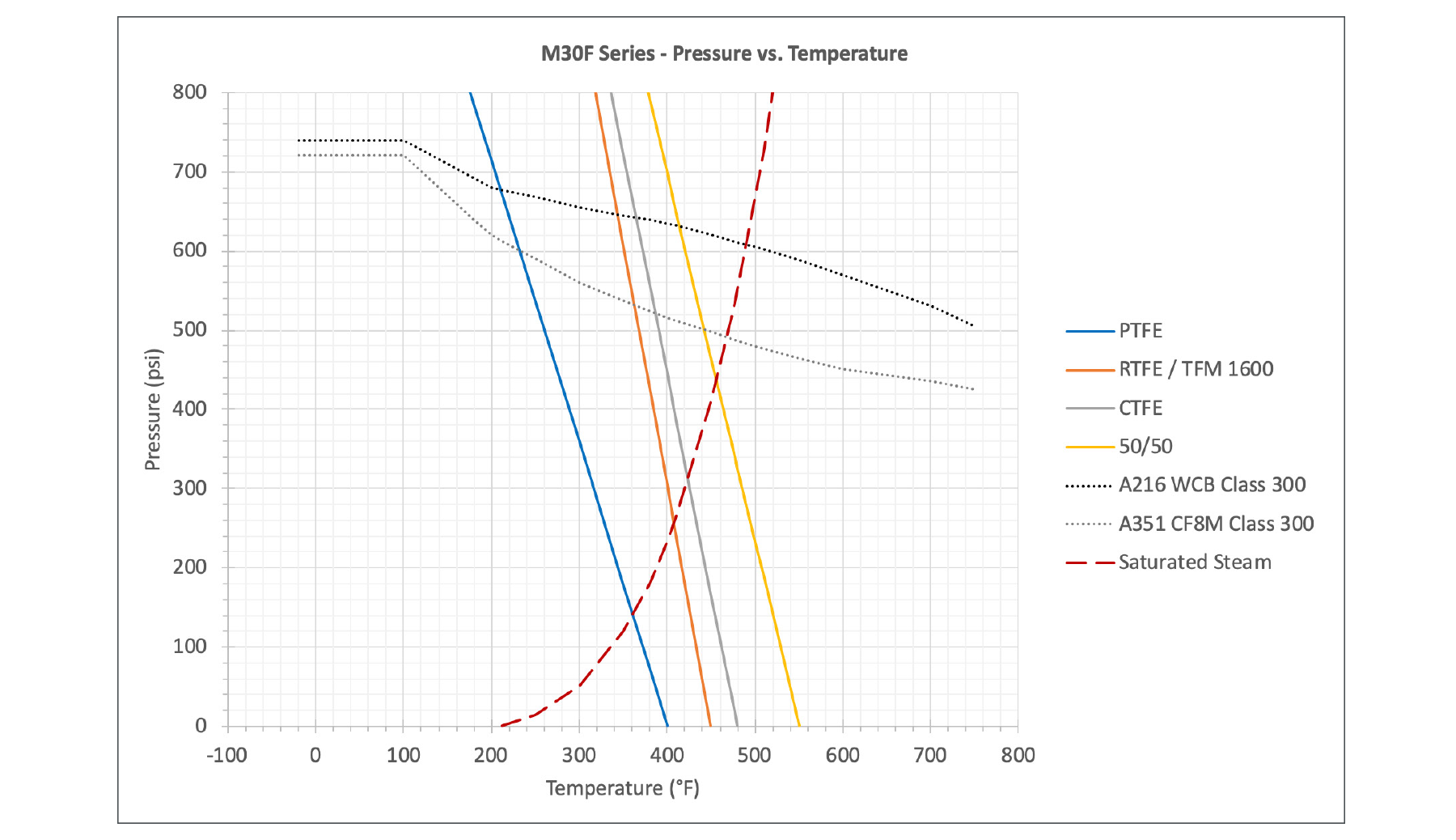

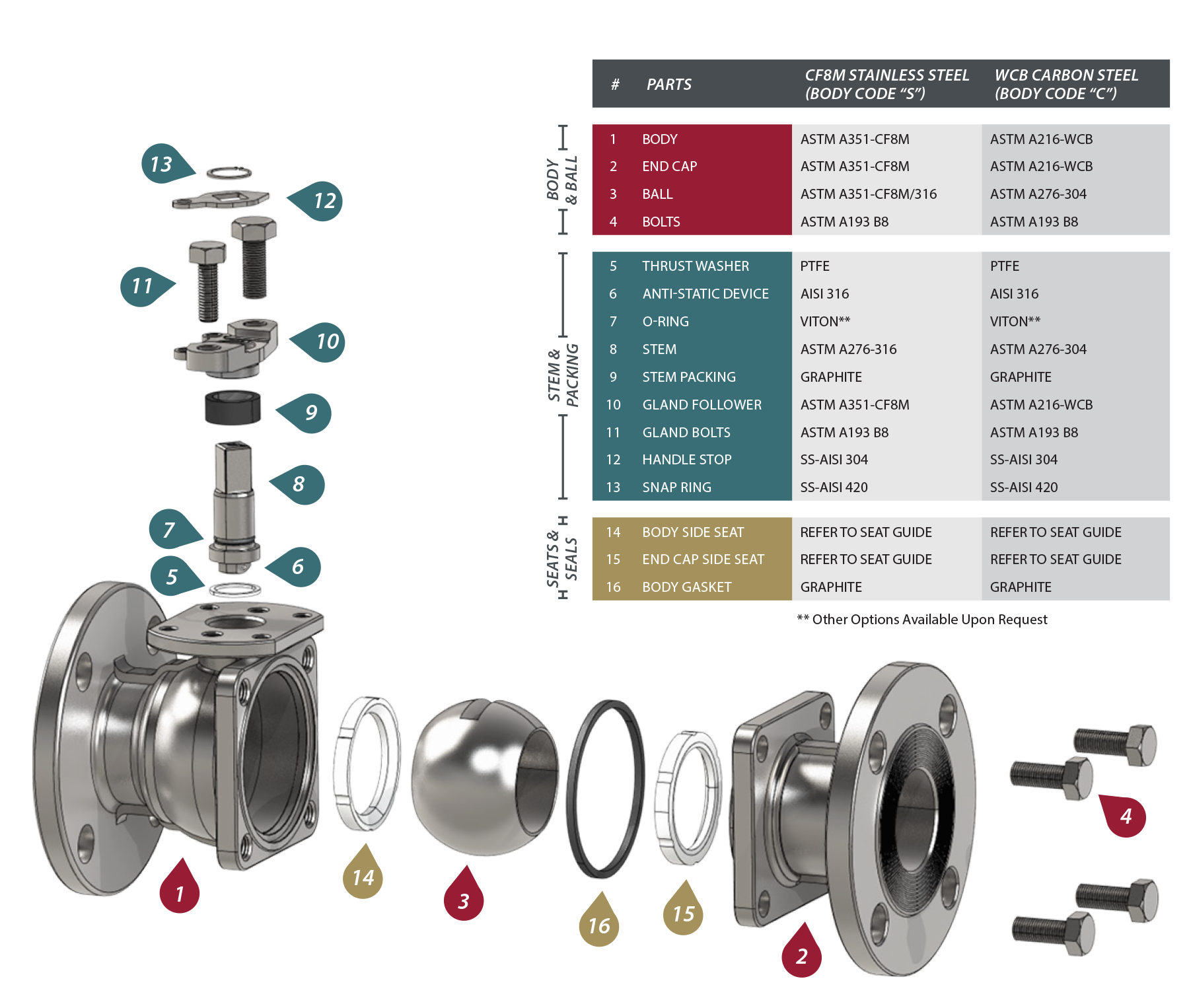

M30F | Firesafe 2-PC Flanged Class 300 | Non-Direct Mount Design

ASME B16.34, API 608, API 607, ISO 15848, NACE MR-0175, Sil 2 Certified, Torques and Tolerances Verified for Consistency

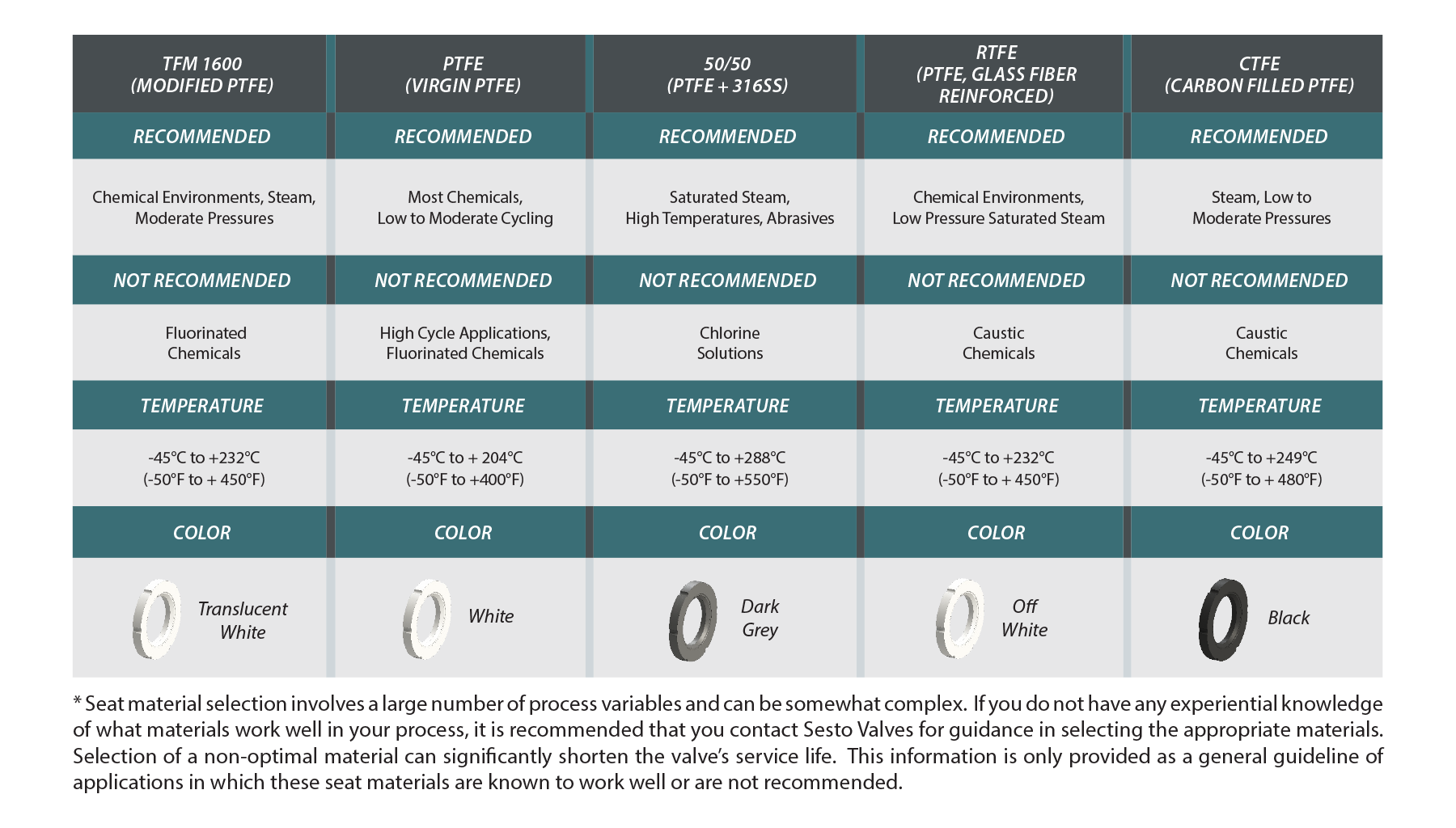

Seat Guide for M15F/M30F

PT Charts for M15F/M30F