- Class 150 to Class 2500

- Size Range ½” thru 36” (Class Dependent)

- Full and Reduced Bore

- Body Wall Thickness ASME B16.34

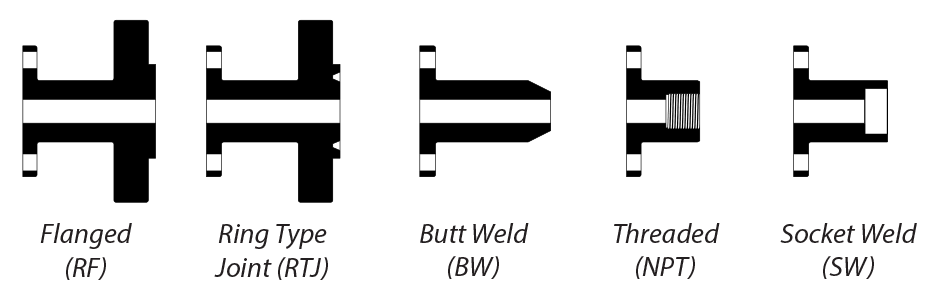

- End Connections: RF, RTJ, BW, SW, NPT, BSP, Special

- Fugitive Emissions ISO 15848

- Fire-Safe Tested API 607

- Emergency Sealant Injectors Optional

- Anti-Static Device and Live-Loaded Packing

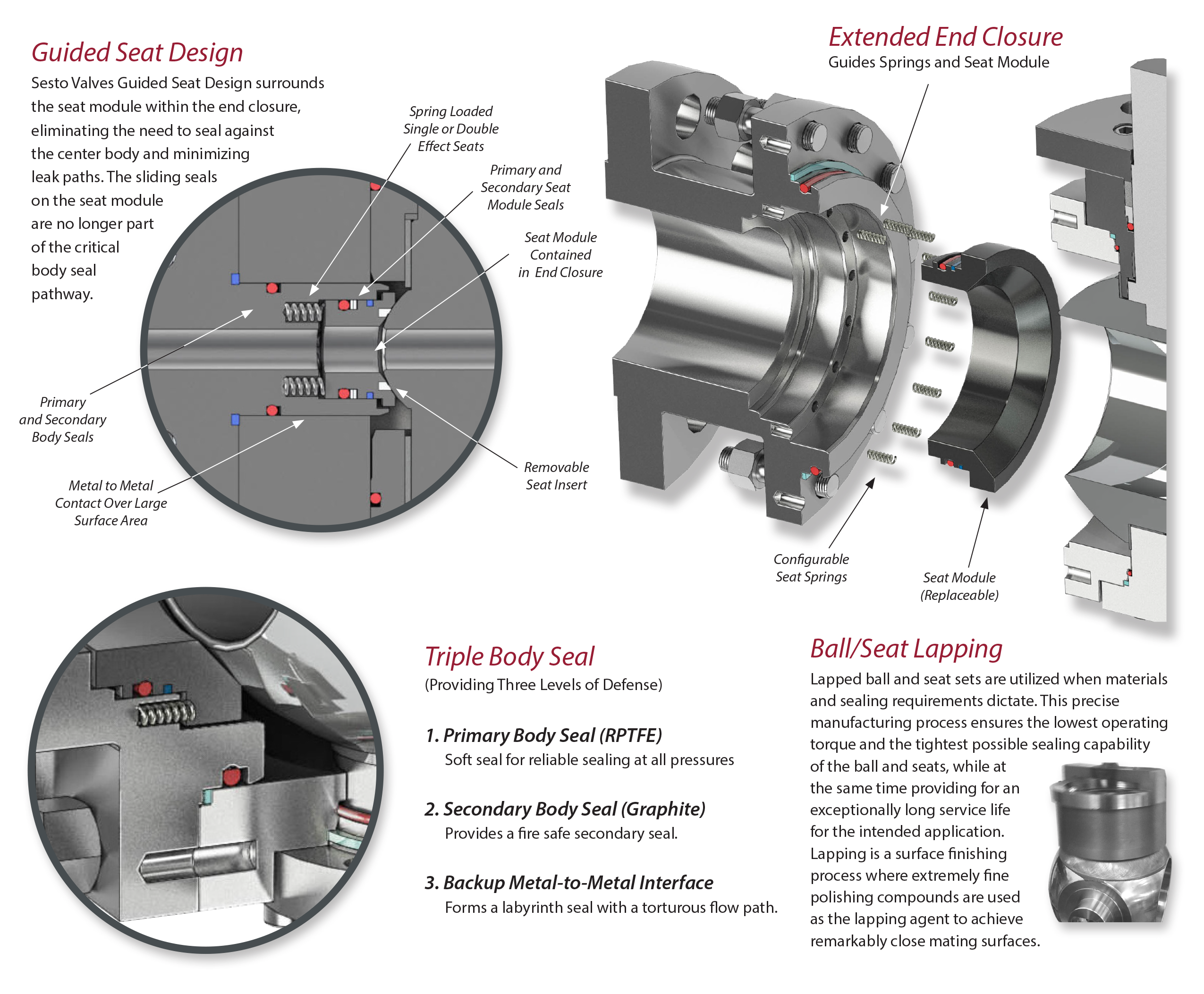

- Guided Seat Design

- Blowout Proof, Low Torque Guided Stem Design

- Wide Range of Soft and Metal Seated Options

- Manual, Electric, Pneumatic, or Electro-Hydraulic Operators Available

- Custom Face-to-Face Lengths Available

- Options: Emergency Shutdown (ESD) Valves, Welded Body for Municipal Heating, Cryogenic, Metal-Seated, Double Block and Bleed, Double Isolation and Bleed

Literature

Certifications & Compliance

Sesto Valves are designed and manufactured to internationally recognized standards including but not limited to the following:

Design: API 6D

Fire Testing: API 607, API 6FA, BS 6755 Part II

Testing: API 6A, API 598, API 17D, ISO 5208, BS 6755 Part I, BS 6364

Marking: API 6A, MSS-SP-25, PED

Certifications: API607, SIL, NACE, MR0175, PED, Fugitive Emissions

Partial List of Applications

- Oil & Gas Pipelines

- Refineries and Petrochemical Plants

- Power Generation

- Gas and Coal Fired Turbines

- District Heating

- Gas Measurement Systems

- Offshore Platforms

- HIPPS Systems

- Cryogenic Service Applications

- Emergency Shut Down Valves

- Pulp & Paper

- Mining

- Boiler Steam and Drain Applications

Fire-Safe &

Fugitive Emissions Certified

Packing arrangement is Fire-Safe for critical applications and Fugitive Emissions ISO 15848 certified.

V-Port Seats Available

Versatility & Reliability

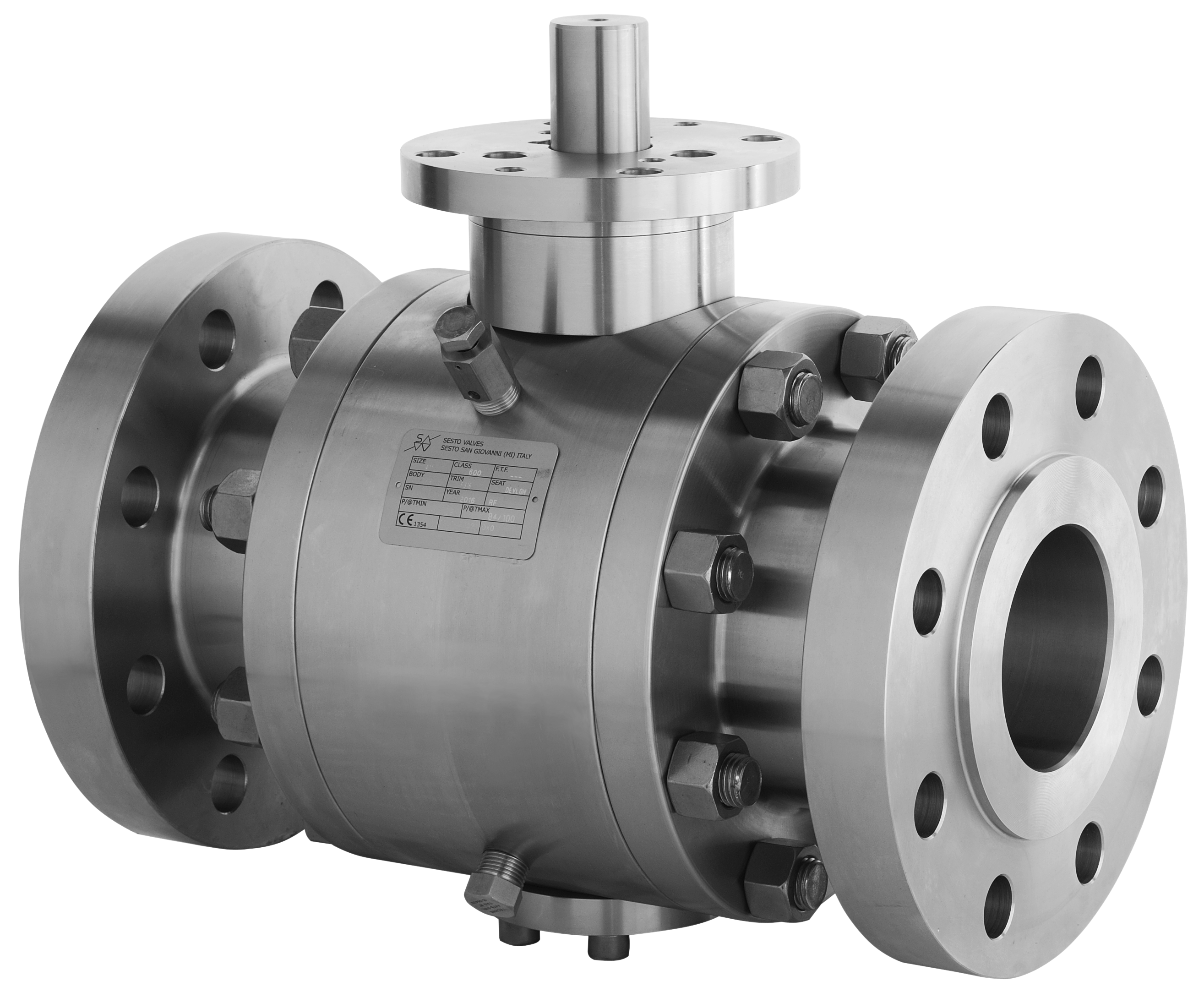

The Sesto Valves trunnion mounted ball valve design allows for the use of all types and materials of construction and may be installed in any flow configuration and orientation. Customizable spring configurations and guided seat design gives the option for a carbon steel body and end enclosures with a duplex or stainless seat module. Metal seated options are available for a variety of high temperature, corrosive, or abrasive applications. Our experienced team of engineers can design and build the right valve for your exact requirements. Sesto trunnion ball valves are Sil 2 certified, fire tested, FE tested, and built for application specific versatility and long term reliability.

End Connections

Why Sesto?

Precision Machined Forged Body

The forged body eliminates the possibility of leakage due to poor castings. Precision finish machining keeps tight tolerances to ensure secure assembly for high pressure,critical applications.

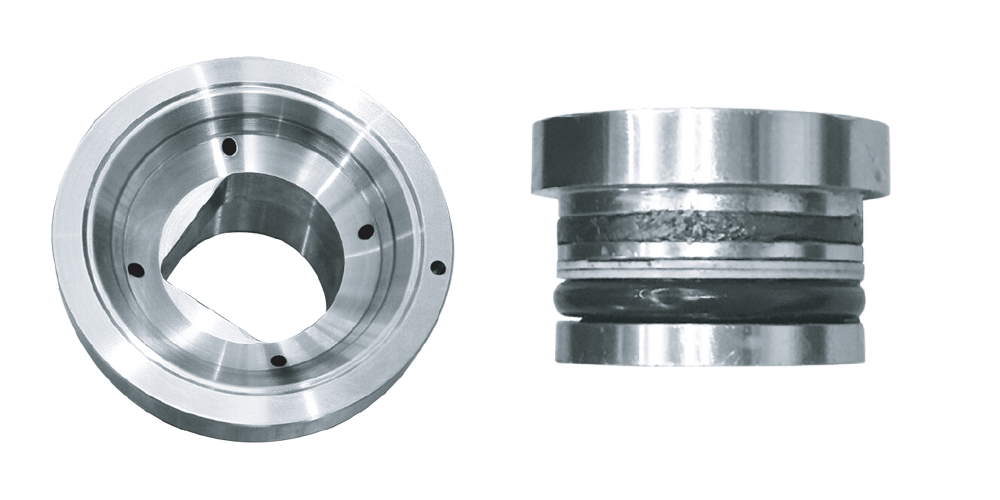

Ball/Seat Lapping

Lapping seats to the ball ensures tight tolerances, improving shut-off sealing capability while lowering torque requirements.

Guided Seat Design

The guided seat design allows for flexibility in materials of construction (end closures vs. seats vs. body), customizable spring configurations for specific pressure relief set points, and ease of maintenance. This design also ensures better concentricity between sealing components to improve sealing performance.

Trunnion Design